Industrial Automation & Monitoring

Modernising, Connecting, and Futureproofing your systems

Contact Us

What We Do

BIJC can develop systems such as SCADA, PLC, MES, OPC, and many others

Ignition SCADA

BIJC are a premier integrator for Ignition. Watch the video below to learn how Ignition can help you

PLC Programming

Allen Bradley, Schneider, Siemens, Mitsubishi, & more

MES

Downtime, OEE, Track & Trace

UNS & MQTT

ISA-95 data hierarchy

Ignition Modules

Custom modules for Ignition

Everything Connected

Some of the industries we serve

We operate in many more industries, so please contact us, no matter your need

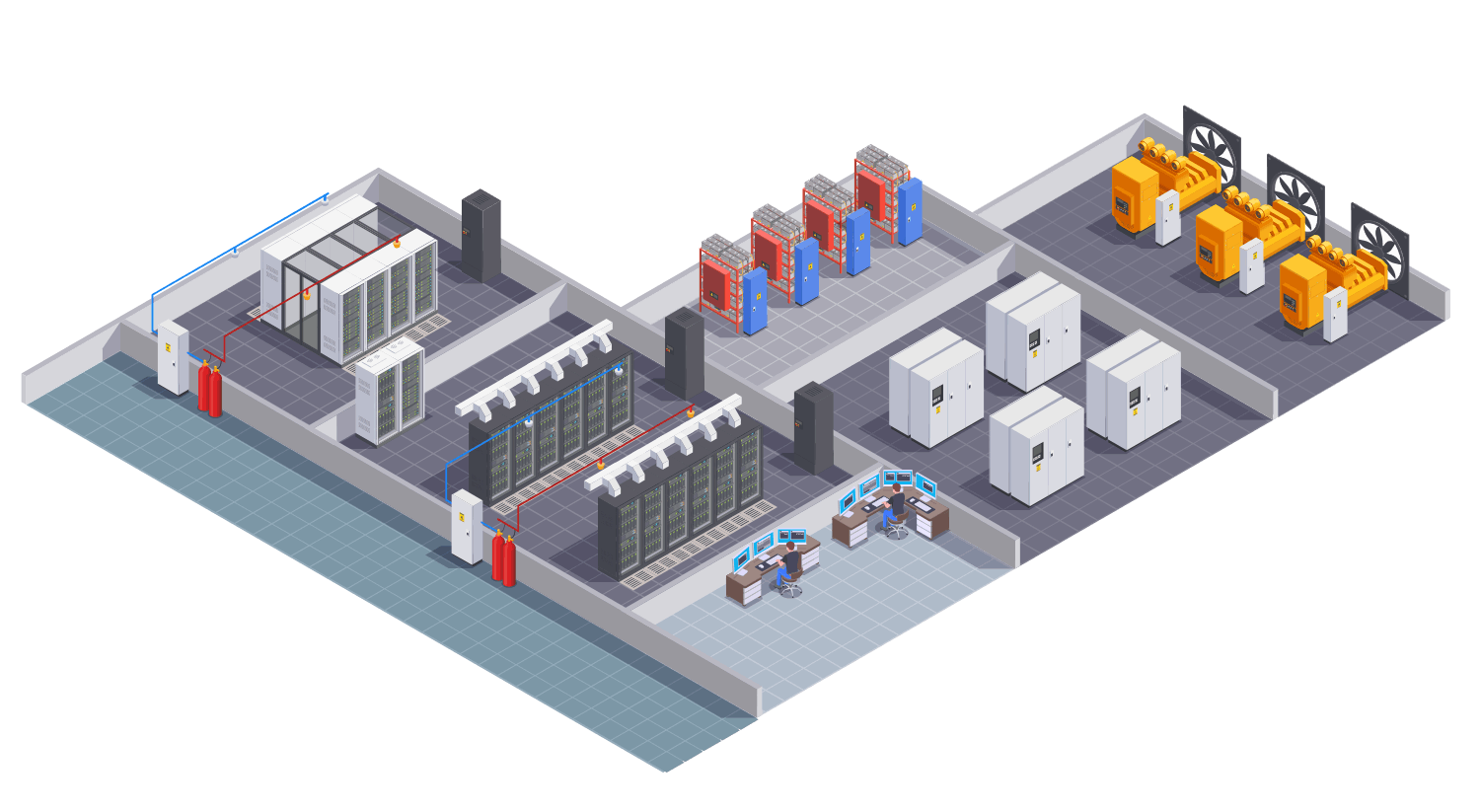

Data Centres

Food & Beverage

Manufacturing

Investment Molding

TRUSTED BY

Award Winning

BIJC are multiple winners of Ignition Firebrand awards, including in 2022 and a community award in 2024

Certified & Compliant

We take our certifications, accreditations and H&S very seriously. As such we have attained Premier Integrator status with Inductive Automation for Ignition and an OEE Downtime Gold Integrator for Sepasoft. BIJC is a certified ISO 9001-2015 and ISO 14001-2015 company, and we are externally audited by SAMS for our H&S, and are SafeContractor and CHAS Approved.

Premier Ignition Integrator

OEE Downtime Gold

CHAS Elite

Safe Contractor Approved

ISO 9001 Certified

ISO 14001 Certified